Diamond Spray

| Project information | |

|---|---|

| Partner | TUM-Oerlikon Advanced Manufacturing Institute (AMI) |

| Period | June 2022 to June 2025 |

| Project-Homepage | https://www.ioc.tum.de/ami/projekte/diamondspray/ |

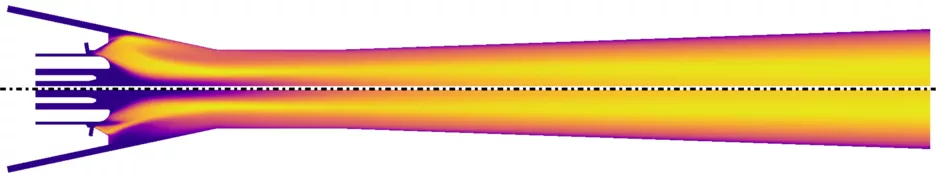

HVOF processes involve combusting oxygen and a fuel to create high pressure and temperature in the combustion chamber. Coating powder, carried by an inert gas stream, is then injected into this hot gas stream, where it melts or partially melts depending on temperature and material. The resulting high-energy gas/powder mixture is accelerated through a specialized nozzle to supersonic speeds before being deposited onto a target surface, facilitated by the high temperature and kinetic energy of the particles. Adapting HVOF torches to operate at lower temperatures but with increased particle velocities is crucial for applications like electric connectors in e-mobility. Meeting customer demands for broader operating conditions and powder materials requires optimizing device design to minimize downtime from nozzle erosion and particle deposition. Developing computational fluid dynamics models is essential to predict and optimize HVOF processes, considering factors like combustion, gas-particle mixing, nozzle design, and process stability.