Lagrangian Advanced MAnufacturer Simulator

General classification

Programming

language

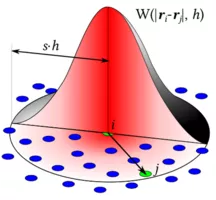

Smoothed Particle Hydrodynamics (SPH) is a meshless Lagrangian method used for simulating physical phenomena such as fluid mechanics. Its key ideas and concepts include representing the fluid as a set of particles, using a kernel function for spatial interpolation, and applying a smoothing length to define the interaction neighborhood of each particle. Compared to classical CFD schemes, SPH offers benefits such as natural handling of large deformations, no need for a mesh, and suitability for problems with complex fluid interfaces and dynamic boundaries. Its features make SPH particularly well-suited for problems involving free surfaces and fluid-structure interactions. The method has been extended to SPH-Arbitrary Lagrangian-Eulerian (SPH-ALE) schemes for applications in shallow water and transient viscoelastic flows, further enhancing its capabilities. LAMAS is entirely written in C++ and builds upon the open-source third-party library OpenFPM for memory handling. The code framework is optimized for usage on acceleration units, such as GPUs, but also performs on classical CPUs making its usage flexible depending on the user demands.

Applications

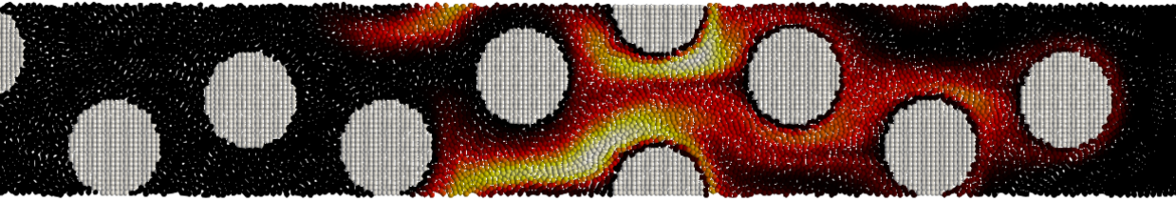

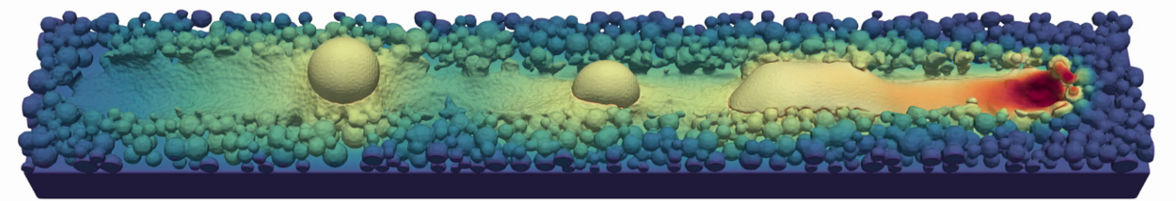

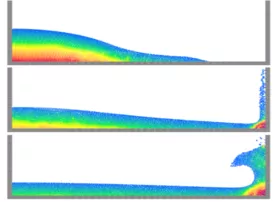

Melt pool dynamics of LPBF

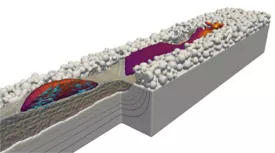

LAMAS, the Lagrangian Additive Manufacturing Simulator, is a simulation framework designed to enhance our understanding of laser-based additive manufacturing (AM) processes, with a focus on laser powder bed fusion (PBF-LB/M). This tool employs the SPH method to model the complex physical aspects of themesoscopic powder-scale continuum in AM. It accurately predicts melt pool characteristicsby considering ultrafast fluid dynamics, Marangoni convection, surface-tension effects, and phase-change phenomena. Ultimately, LAMAS aims to deepen our understanding of the physics of laser-based AM by numerical simulations. To this end, we have conducted several studies, e.g., we investigated the influence of different gas atmospheres on the melt pool morphology and heat balance of an aluminum alloy, studied the steady state and transient transition from conduction to keyhole mode with a titanium alloy, generated virtual process maps and investigated different beam shaping strategies to suppress balling defects for stainless steel.

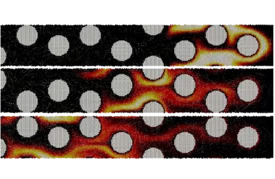

Balling defects

Interaction of multiple lasers

Keyhole mode

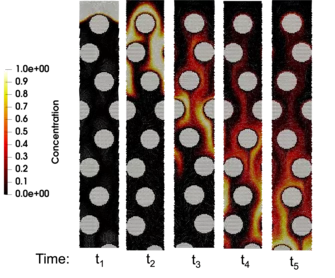

Liquid chromatography simulations

Using the Smoothed Particle Hydrodynamics method to explore liquid chromatography, with a particular focus on fluid mechanics and species transport, holds immense promise. The numerical study of fluid mechanics in chromatographic columns enables the optimization of column design and enhanced separation efficiency. Investigating species transport allows for a refined understanding of mass transfer, diffusion, and convection, fostering the development of more accurate predictive models. This research not only contributes to the optimization of current chromatographic techniques but also opens avenues for innovative approaches that can revolutionize separation in diverse scientific and industrial applications.

Species transport

Porous column

Publications

Wimmer, A., Yalvac, B., Zöller, C., Hofstaetter, F., Adami, S., Adams, N. A., & Zaeh, M. F. (2021): Experimental and Numerical Investigations of In Situ Alloying during Powder Bed Fusion of Metals Using a Laser Beam, Metals, 11, 1842.

Zöller, C., Adams, N. A., & Adami, S. (2023): A partitioned continuous surface stress model for multiphase smoothed particle hydrodynamics. Journal of Computational Physics, 472, 11716.

Zöller, C., Adams, N. A., & Adami, S. (2023): Numerical investigation of balling defects in laser-based powder bed fusion of metals with Inconel 718. Additive Manufacturing, 73, 103658.

Wimmer, A., Panzer, H., Zöller, C., Adami, S., Adams, N. A., & Zaeh, M. F. (2023): Experimental and numerical investigations of the hot cracking susceptibility during the powder bed fusion of AA 7075 using a laser beam, Progress in Additive Manufacturing.