Utilisation and Application

Application and use of the Power-to-X products: hydrogen, methane, methanol or synthetic fuels

Investigation of motor use, injection in turbines, electrochemical reconversion and material aspects (e.g. use in the chemical and process industries).

Simulative investigation of the storage of cryogenic compressed hydrogen gas for long-distance commercial vehicles and of gaseous hydrogen in so-called multi-element gas carriers (MEGC), as well as the supply chain of hydrogen in aviation

Reducing greenhouse gases in the mobility sector is one of the most important challenges to stop climate change. Besides battery technology, hydrogen-fueled vehicles are the focus of research and development. Especially for long-distance commercial vehicles, the hydrogen fuel cell is an ideal solution. For this purpose, a highly efficient hydrogen tank is required. The storage of cryogenic compressed hydrogen gas (CcH2) is a promising storage technology and enables high storage densities.

However, storage technologies with gaseous hydrogen can also be used advantageously for the regional, decentralized production and distribution of hydrogen. A particular focus here is on so-called multi-element gas carriers (MEGC). MEGCs are transportable hydrogen storage containers in which hydrogen is stored in several pressure vessels at elevated pressure and ambient temperatures.

Also in aviation, the use of green hydrogen as a propulsion system for larger commercial aircraft offers significant potential for emission reduction. Alongside the development of new propulsion systems and aircraft concepts, establishing a corresponding hydrogen infrastructure is crucial. Creating long-term perspectives and defining transition pathways within the framework of a global energy transition are central to this endeavor. This requires a comprehensive examination of the technical, economic, and ecological aspects of the supply chain, which is addressed in the institute’s research.

Website: Research at APT

Contact: Sebastian Rehfeldt

Component and System Modeling of Hydrogen Supply Networks for Air Transport

The use of green hydrogen as a propulsion system for larger commercially used aircraft is a promising alternative to enable more environmentally friendly aviation. However, it is essential that hydrogen is produced from renewable energy sources to make a contribution to climate protection. In addition to the development of new propulsion systems and aircraft concepts, the establishment of a corresponding hydrogen infrastructure is one of the biggest challenges in order to enable competitive operating costs for the new aircraft.

The joint project HyNEAT (Hydrogen Supply Networks' Evolution for Air Transport) is developing concepts for global hydrogen supply infrastructures for use in hydrogen-powered aircraft. The aim is to present long-term perspectives and possible transition paths in line with a global energy transition and to derive recommendations for action for politics and industry.

To enable techno-economic investigations and optimizations of hydrogen supply networks, the Institute of Plant and Process Technology considers the components of such hydrogen supply chains. These include hydrogen liquefaction plants, storage tanks, compressors, and pumps, among others. Through dynamic component and overall system models, the entire hydrogen supply chain from production to aircraft will be described both thermodynamically and techno-economically. Derived from the component and overall system modeling, concrete business models will also be considered.

Type: Collaborative project: HyNEAT (Hydrogen Supply Networks‘ Evolution for Air Transport)

Funding: German Federal Ministry of Education and Research (BMBF)

Funding code: 03SF0670F

Runtime: 01.04.2023 - 31.03.2026

Website: HyNEAT

Contact: Laura Stops

Further information: HyNEAT Website

Development of a cryogenic hydrogen gas storage for application in long-distance commercial vehicles

The development and optimization of a cryogenic hydrogen tank system in application for trucks is the focus of the CryoTRUCK research project. The scientific work is to set up appropriate thermodynamic models and simulation models for heat transfer and cold storage. Based on this, the processes of refueling and fuel withdrawal will be simulated dynamically. Experimental investigations on cold storage systems are also planned with the project partners. Both the modelling and the experimental validation are the basic building blocks in order to integrate the CcH2 storage system into vehicles.

Type: Collaborative project: CryoTRUCK

Funding: German Federal Ministry for Digital and Transport (BMDV)

Funding code: 03B10411E

Runtime: 01.01.2022 - 31.05.2025

Website: CryoTRUCK

Contact: Johannes Hamacher, Alexander Stary, Daniel Siebe, Laura Stops

Development and demonstration of two technologies for the refueling of aircrafts with liquid hydrogen: Direct refueling and tank swap technology

The objective of the project is to develop two refueling technologies and demonstrate them at airports in Milan and Paris. The direct refueling of an aircraft with liquid hydrogen and a tank exchange technology in which an empty tank is replaced by a full tank are being investigated. The Institute of Plant and Process Technology is working on the development and modeling of a direct refueling system based on a liquid hydrogen centrifugal in cooperation with Linde plc. The required pump is being developed and tested in a test facility. In addition, a dynamic model for the loading and unloading processes of liquid hydrogen is being developed and used to optimize the overall system.

Type: EU project ALRIGH2T

Funding: European Climate, Infrastructure and Environment Executive Agency (CINEA)

Funding code: 101138105

Runtime: 01.01.2024 - 01.01.2028

Website: ALRIGH2T

Contact: Fabian Primke

Further information: ALRIGH2T Website

Internal Combustion Engines can be used to apply synthetic fuels in propulsion and generation of electric energy in a cost- and energy-efficient way and with lowest pollutant emissions. The modification of engine concepts for new fuels will further improve efficiency and exhaust after-treatment significantly compared to conventional fuels. In various applications combustion engines are increasingly combined with electric drives. This makes it necessary to develop hybrid systems which can fulfill the ambitious requirements of a future sustainable energy economy.

Website: Research at NMA

Contact: Dr.-Ing. Martin Härtl

- E-Fuels from waste-CO2 of steel production

- BEV with generator set running on green methanol

- Characterisation and optimisation of prototype genset

Type: Collaborative project

Funding: German Federal Ministry of Education and Research (BMBF)

Funding code: 03EW0019D

Runtime: 01.08.2021 - 31.07.2025

Contact: Patrick Fitz

- Hydrogen-powered high-displacement piston engine research for maritime applications

- Optimization of combustion process and tribology for achieving commercially viable power density and efficiency

- Application of state-of-the-art development methods by TUM and industry partners

Type: Collaborative project

Funding: German Federal Ministry of Economic Affairs and Climate Action (BMWK)

Funding code: 03SX570B

Runtime: 01.09.2022 - 31.08.2025

Contact: Dr.-Ing. Maximilian Prager

Chair of Turbomachinery and Flight Propulsion (LTF)

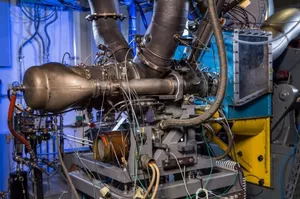

Combustion characteristics of sustainable fuels in helicopter engines

Research on hydrogen and its derivatives at LTF is focused on experimental investigations of various sustainable fuels on an Allison 250 C20B helicopter engine with respect to performance and emissions.

Website: Research at LTF

Contact: Alexander Rabl

Small Aero Engines - Performance and Emissions using Drop-In Fuels

Alternative fuels can be used to achieve a rapid reduction in the climate impact of aviation, In addition to electric aircraft engines or the use of hydrogen as a fuel.

In the project, funded by Munich Aerospace e.V., the behavior of a small gas turbine with regard to performance, engine health, and the resulting emissions will be investigated using alternative fuels. The following questions are to be examined in more detail:

- What is the fuel-specific impact on engine operability?

- What changes in engine performance are seen in steady-state and transient operation?

- How do different drop-in fuels, sustainable aviation fuels, or eFuels affect emissions?

Regarding engine emissions, both gas phase and particulate emissions are considered.

The experiments will take place on the institute's own Allison 250 C20B helicopter engine. This turboshaft engine is very compact, and the individual components are easily accessible, facilitating adjustments and operation. This makes it possible to integrate new measurement technology easily. With regard to the fuel system, it is possible to switch quickly between regular Jet A-1 feed and alternative fuel feed.

More details about the Allison gas turbine test stand can be found here.

Type: Munich Aerospace Scholarship

Funding: Munich Aerospace e.V.

Funding code: not available

Runtime: 01.08.2021 - 31.07.2024

Website: Green Aerospace - Munich Aerospace – New Horizons in Aviation and Space

Contact: Alexander Rabl

Further information: ASAF at LTF

Mobility and Transport: Powering Aviation

The "Flightpath 2050 - Europe's Vision for Aviation" report formulates the goal of significantly reducing CO2 and NOx emissions as well as noise emissions. With our research, we are making a contribution to the formulated goals. In particular, the switch from kerosene to hydrogen is intended to contribute to the decarbonization of engine emissions.

Website: Research at SFM

Contact: Katharina Meinecke

Reliability and Safety

Gas mixtures consisting of large amounts of hydrogen (H2) and carbon monoxide (CO) are extensively used in chemical engineering processes, e. g. syngas from reforming or gasification. However, depending on the composition, the gas mixture exhibits a wide explosive range. Consequently, understanding and predicting the conditions for handling the mixture safely is of importance. Especially, the potential development of a H2/CO mixture in severe accident scenarios of nuclear power plants is of great concern and requires research on a fundamental level.

Website: Research at SFM

Contact: Kajetan Planötscher

Chemical kinetic mechanisms for SAF

Detailed study on automated chemical kinetic mechanism generation and reduction for SAF surrogates

Due to the ever-more urgent problem of global warming, the aviation industry is looking towards using Sustainable Aviation Fuel (SAF). While using SAF leads to a reduction in CO2 emissions, and might even result in net carbon neutrality, the problem of non-CO2 emissions, like nitrogen oxides (NOx) and soot, is not directly tackled.

The SAFMech project aims to investigate the chemical-physical processes involved in the combustion of Fischer-Tropsch (FT) and Alcohol to Jet (ATJ) type SAF surrogates, using innovative computational/numerical methods and making the advances usable for industrial application.

The work involves the generation of detailed chemical kinetic mechanisms for SAF surrogates using the Reaction Mechanism Generator (RMG) software, followed by the development of software for mechanism reduction and optimization while maintaining the accuracy of the detailed mechanism as best as possible. These reduced kinetic mechanisms, along with fluid dynamics models, are used to predict essential combustion characteristics. Furthermore, due to their role in soot nucleation and growth, the study also aims to provide a more detailed insight into the formation of polycyclic aromatic hydrocarbon (PAH).

“SAFMech” contributes to the environmental protection objectives of “Flightpath 2050” with respect to its noise reduction and environmental compatibility objectives of aircraft engines.

Type: Bavarian aviation research program (BayLu25)

Funding: Bavarian State Ministry of Economic Affairs, Regional Development and Energy

Funding code: BayLu25 - BLU-2109-0028

Runtime: 01.07.2022 - 30.06.2025

Website: Powering Aviation - Professur für Sustainable Future Mobility

Contact: Pooja Neema, Michael Geuking

H2 Combustion

Investigation of the physical phenomena related to the hydrogen-air combustion of future hydrogen-powered aircraft engines.

To reduce the climate impact of aviation, decarbonization is a major challenge. Current combustion chambers are burning hydrocarbon fuels, such as kerosene or, more recently, emerging SAF products. Hydrogen is also considered today as a promising energy carrier but burning hydrogen creates radically new challenges which need to be understood and anticipated.

HESTIA focuses on increasing the scientific knowledge of hydrogen-fuelled aero-engines. The related physical phenomena will be evaluated through fundamental experiments. This experimental work will be closely coupled to numerical activities by project partners who will adapt or develop models and progressively increase their maturity so that they can be integrated into industrial CFD codes.

Type: European Commission within the Horizon Europe Programme

Funding: European Commission: Climate, Energy and Mobility

Funding code: 101056865

Runtime: 01.09.2022 - 31.08.2026

Website: European Comission - HydrogEn combuSTion In Aero engines

Contact: Katharina Meinecke

H2 Combustion

Investigation and development of combustion processes with the lowest nitrogen oxide emissions ("Low NOx") for hydrogen in aircraft engines.

Compared to RQL combustion in hydrogen-fueled aero engines, the state of knowledge for technically premixed combustion with hydrogen in aircraft engines is still far behind. This applies to the conceptual level as well as to the optimization of promising concepts. However, the further development of premixed hydrogen combustion is expected to bring several benefits especially regarding the reduction of NOx emissions. This project therefore investigates the behavior of an innovative, premixed injection and combustion concept which is suitable for the use of hydrogen. Therefore, steady-state (mixture formation and heat release distribution) and transient (ignition, start-up and shutdown) behavior will be evaluated and thermoacoustic investigation of premixed combustion with lowest NOx emissions will be conducted. GE Aerospace will design the injection and combustion system and deliver them to TUM where the above-mentioned experiments will be performed.

In addition, a novel axially staged system will be developed at TUM and first functional tests will be performed. This system is intended to apply the developed technology for staged hydrogen combustion from stationary gas turbines to aircraft engines, thus paving the way for new approaches to emission reduction. The staged system has an increased reduction potential compared to the non-staged one. To meet the demands in various flight conditions and thus different load requirements, the stages are tailored to different operating points in various configurations. This concept is first designed through simulation and then experimentally tested, with measurements focusing on emissions.

Type: Collaborative project: H2-Low NOx Combustor & Conditioning for Start-up

Funding: Federal Ministry for Economic Affairs and Climate Action

Funding code: 20M2211D

Runtime: 01.11.2023 - 31.12.2026

Website: Powering Aviation - Professur für Sustainable Future Mobility

Contact: Adrian Hochmuth, Maximilian Aubel

H2 Combustion

The project “Greener-RQL” supports the development of new hydrogen aircraft engines by focusing on the causes of the Growl/Rumble phenomenon.

The Growl/Rumble-phenomenon describes a low frequency noise, which can be perceived in the aircraft cabin as unpleasant and risks to damage the engines. Entropy and equivalence ratio waves are suspected as possible causes for this phenomenon. However, well-founded research is still lacking, especially in the context of hydrogen use.

To address this shortcoming “Greener-RQL“ investigates the convection of entropy waves and equivalence ratio waves as well as their feedback mechanism with acoustic waves inside an aero engine combustion chamber with air-staging (RQL).

RQL combustion chambers are a concept which traditionally reduce nitrogen oxide emissions. This type of chamber divides combustion into two stages. In the first stage, combustion occurs with excess fuel in the rich regime. While in the second stage, additional air is added and combustion occurs under excess air in the lean regime. This allows to evade combustion near the stochiometric regime, high temperatures, and associated nitrogen oxides production.

“Greener-RQL”, supported by the Bavarian aviation research program “BayLu25”, contributes to the environmental protection objectives of “Flightpath 2050” with respect to its noise reduction and environmental compatibility objectives of aircraft engines supporting the development of hydrogen engines.

Type: Collaborative project: Combustion dynamics of RQL combustion chambers

Funding: Bavarian Ministry of Economic Affairs, Regional Development and Energy

Funding code: BLU-2109-0012 / BayLu21-007-B

Runtime: 31.12.2021 - 31.12.2024

Website: Powering Aviation - Professur für Sustainable Future Mobility

Contact: Thuy An Do, Ángel Brito Gadeschi

H2 Combustion

Thermoacoustic Investigations of hydrogen in RQL combustion chambers

Compared to the combustion of kerosene-fueled aero engines, the degree of knowledge on hydrogen combustion in the aviation sector is still significantly low. This applies both for the conceptual level and also the optimization of promising approaches. In this project, the strategy of air staging with RQL (Rich-Quench-Lean) combustion, which is common in kerosene operation, is to be built upon. This approach significantly reduces pollutant emissions by means of multi-step combustion. Due to the highly different physical and chemical properties of hydrogen compared to kerosene, the behavior of innovative injection and staging scenarios suitable for hydrogen combustion will be investigated. In this context, the steady-state behavior, such as mixture formation and heat release distribution, as well as the transient behavior with respect to ignition, start-up, and safe shutdown, are examined. In addition, a high degree of attention will be paid to possible thermoacoustic combustion instabilities. The project is part of a larger research network in order to progress towards the safe and reliable combustor technology of the future for hydrogen propulsion.

Type: Collaborative project: Adaptation of the Rich-Quench-Lean principle to hydrogen-powered combustion chambers

Funding: Federal Ministry for Economic Affairs and Climate Action

Funding code: 20M2106C

Runtime: until 31.03.2026

Website: Powering Aviation - Professur für Sustainable Future Mobility

Contact: Benjamin Kölbl , Jannes Papenbrock

Combustion process of H2 /CO/air mixtures

Determination of Characteristics of Slow to Fast H2-CO Combustion and Derivation of Risk Criteria

Conditions that might jeopardize the integrity of the containment in nuclear power plants can occur for example, if the fuel rods are damaged and H2 is formed through metal oxidation reactions – particularly zirconium oxidation. Further, concrete-melt interaction (Molten Core Concrete Interaction - MCCI) can occur, in which CO is released in addition to H2. Due to buoyancy effects, the gas mixture accumulates under the roof of the building establishing a stratified, semi confined gas layer. If H2 or H2/CO is present together with oxygen (O2) in a sufficient concentration, ignition by hot surfaces or sparks is highly probable. The combustion process that follows might increase the pressure and temperature. In particular, fast turbulent-accelerated combustion and deflagration to detonation transition (DDT) or detonation are safety relevant, since related high local pressure peaks might damage the integrity of building structure. In worst case assumptions the outer barrier between the nuclear inventory and the environment might be destroyed, e.g., Fukushima 2011 [1].

Aiming to avoid similar severe accident events in the future, the present research project H2CORisk is going to improve the scientific understanding by providing new experimental insights into deflagrative combustion processes of H2/CO/air-mixtures in partial containment. Specifically, conventional and optical measurement techniques are going to be used to obtain results that allow for the derivation of a sigma criterion for flame acceleration. Furthermore, the experimental results are going to be used for validating simulation results generated by an OpenFoam based CFD code under development at the Chair of Thermodynamics, TUM. H2CORisk is part of the KEK program (Competence preservation in Nuclear Technology at GRS).

[1] R. Gauntt, D. Kalinich, J. Cardoni, J. Phillips, A. Goldmann, S. Pickering, M. Francis, K. Robb, L. Ott, D. Wang, et al. Fukushima daiichi accident study (status as of april 2012). Sandia National Laboratory Report, SAND2012-6173, Albuquerque, NM, 2012

Type: Initiative “Maintaining competence in Nuclear Technology ”

Funding: Federal Ministry for Economic Affairs and Climate Action

Funding code: 1501642

Runtime: 01.12.2021 - 30.11.2024

Website: Powering Aviation - Professur für Sustainable Future Mobility

Contact: Kajetan Planötscher

Associate Professorship of Thermo-Fluid Dynamics (TFD)

Thermo-acoustic combustion instabilities in hydrogen combustion

Research of the TFD group focuses on thermoacoustic combustion instabilities. These impair the security and reliability of gas turbines and rocket motors as well as domestic or industrial burners.

The use of carbon-neutral energy carriers such as H2 or NH3 introduces particular challenges with regard to flame stability. In order to analyse and control instabilities, fluid mechanics, acoustics and combustion science are combined in an interdisciplinary approach with methods of system identification and control theory. Intensive exchange with colleagues from research institutes in- and outside Europe furthers our efforts.

Website: Research at TFD

Contact: Prof. Dr. Wolfgang Polifke

The objective of the project is to determine and evaluate the thermo-acoustic properties of a combustor test rig. This is important for the comparison of current kerosene-based technologies with future hydrogen combustion concepts, particularly with regard to flame dynamics and thermo-acoustic stability.

The aim of the project is the numerical investigation of the flame dynamics of kerosene and hydrogen flames. For this purpose, high-resolution CFD methods are combined with system identification to estimate the frequency-dependent flame and entropy response to acoustic excitations. These data will be integrated into models of combustion chamber acoustics in order to analyse the thermo-acoustic stability. The results will be validated with numerical and experimental data.

In summary, the project provides a numerically/experimentally supported investigation of the thermo-acoustic stability of a combustion chamber for 100% hydrogen combustion. This supports the national hydrogen.

Type: LuFO VI

Funding: German Federal Ministry for Economic Affairs and Climate Action (BMWK)

Runtime: 01.04.2023 - 31.03.2027

Contact: Clément Mocquard

Lehrstuhl für Technische Elektrochemie (TEC)

Brennstoffzellenlösungen zur Erzeugung elektrischer Energie aus grünem Wasserstoff

Research at the Chair of Technical Electrochemistry regarding the usage of PtX products focusses on proton exchange membrane (PEM) fuel cells to generate electrical energy. Topics include catalyst synthesis and catalyst layer design based on platinum group metals (PGM) as well as the development and characterization of PGM-free catalyst materials. Furthermore, transport processes in catalyst and gas diffusion layers are investigated and optimized. Performance and durability testing with in situ and ex situ diagnostics is performed, to gain a deeper understanding of degradation mechanisms.

Website: Fuel cell research at TEC

Contact: Matthias Kornherr

The key technologies to master the change to a sustainable economy are no longer under development; they are on the table and ready for industrial rollout. The CTV group’s research focuses on bringing sustainable processes to practice, being engaged in projects on renewable fuels and CO2 capture to boost a more sustainable energy sector.

Website: Research at CTV

Contact: Dr. Junior Staudt

In the SynergyFuels project, nine plants for the synthesis of e-fuels and biofuels are integrated into a refinery concept in both material and energetic terms. The use of biogenic residues is combined with power-to-X processes. In this way, synergies are created: The combination increases both material and energy efficiency in the production of the fuels. The project aims to scale up processes for the production of renewable fuels to pre-production scale in the short term.

The Chair of Chemical Process Engineering (CTV) coordinates the SynergyFuels project. Besides, CTV takes part in 3 more workpackages within the project, working with the synthesis and purificatin of Formaldehyde and Ethers.

Type: Cooperative Project Synergy Fuels: Synergies by Integrating the Use of Biomass and Power-To-X for the Production of Renewable Fuels

Funding: Federal Ministry for Digital and Transport (BMDV)

Funding code: 16RK34003A

Runtime: 01.01.2023 - 31.12.2026

Website: SynergyFuels

Contact: Jakob Burger, Júnior Staudt

Further information: synergyfuels(at)cs.tum.de

Renewable alternatives to conventional kerosene are increasingly becoming the focus of aviation for ecological and economic reasons. In this diverse field, the "Alternative Fuels " research at Bauhaus Luftfahrt focuses on the following key questions:

- What quantities can be produced worldwide in a sustainable manner in the future?

- Which technical production pathways are available for a long-term supply?

- And how should these pathways be evaluated in terms of their technical, environmental, and socioeconomic potential?

Technological options with long-term future potential play a special in the considerations carried out by Bauhaus Luftfahrt. Important research topics in the field of alternative fuels are the production of advanced biofuels with raw materials such as waste and residual materials, as well as non-biogenic fuels, e.g. power-to-liquid (PtL), solar-thermochemical fuels (sun-to-liquid - StL) and hydrogen.

Website: Research at BH Luft