Modeling of H2 tanks for trucks - new publication at the Institute of Plant and Process Technology

TUM.PtX News | created by Laura Stops

Due to the growing urgency to reduce greenhouse gas emissions and the increasing adoption of hydrogen as a sustainable fuel, the challenge of storing hydrogen efficiently onboard vehicles has become vital in the transition to a greener future. Thus, at the Institute of Plant and Process Technology, we investigate cryo-compressed hydrogen tanks and their key components for application in heavy-duty trucks in the joint project “CryoTRUCK.”

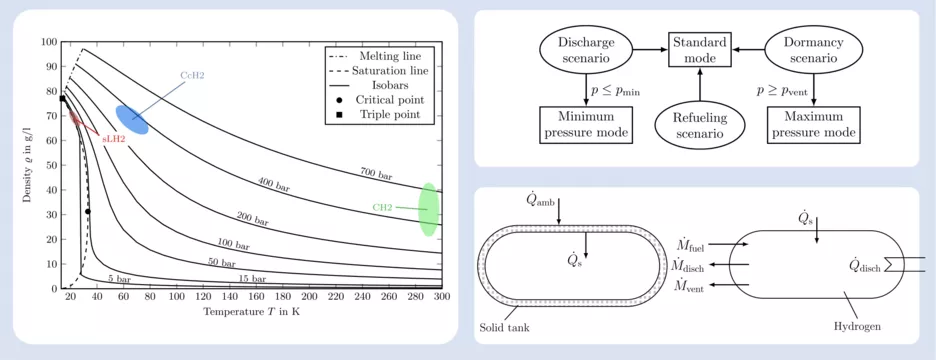

To ensure efficient storage and optimal operation, it is key to understand the thermodynamic processes in such tanks, especially when considering cryogenic storage conditions. Thus, we are excited to share our latest research paper, which focuses on the development of a generalized thermodynamic model for cryogenic hydrogen storage tanks in heavy-duty trucks. The presented modeling approach allows us to describe the thermodynamic state of the hydrogen in all typical operational conditions, including those within the two-phase region. Thereby, a single set of differential-algebraic equations (DAE) and the DAE-solver ode15s from Matlab are applied. Only three equations are automatically switched by a smart decision logic whenever operational modes change. Subsequently, the model is applied to a drive cycle study comparing three currently developed options for storing hydrogen physically onboard trucks: cryo-compressed hydrogen (CcH2), subcooled liquid hydrogen (sLH2), and compressed gaseous hydrogen (CH2). Our findings show, amongst others, that CcH2 offers the highest driving ranges due to its superior storage density, making it a promising solution for sustainable transportation.

Please find the full article here: https://doi.org/10.1016/j.cryogenics.2024.103826