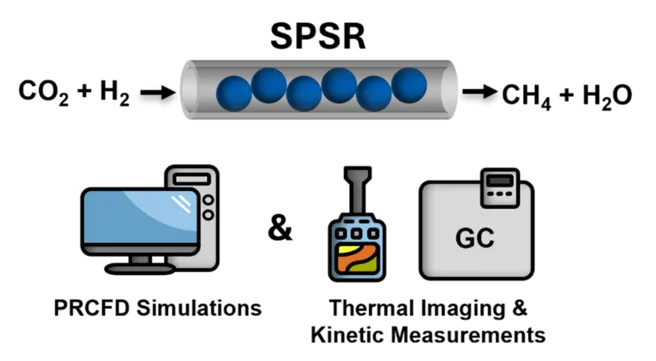

Heterogeneous catalysis plays a crucial role in the chemical industry, particularly in the effective and sustainable production of numerous products. Consequently, it is essential to improve catalytic processes, which can be achieved by developing new catalyst systems and reactor designs. In catalyst development, evaluating catalytic activity is a crucial step, that is constantly improved. To save on resources when testing new catalysts, reactors are designed as small as possible, which has led to the development of the single pellet string reactor (SPSR). This type of reactor is characterized by its diameter, which is only slightly larger than the catalyst pellets. Despite its compact design, the SPSR has comparable dispersion and mass transfer properties to larger reactors and is therefore particularly suitable for kinetic testing of catalyst pellets.

In the publication, heat and mass transfer limitations in catalyst pellets are investigated, which have significant influences on catalyst activity and need to be considered in the evaluation. With increasing flow rates, an increase in limitations was found for the exothermic CO2 methanation, negatively impacting the conversion. The internal mass transfer limitation was found to be particularly critical. Additionally, heat dissipation via the reactor wall was identified as an influential parameter on the activity.

Overall, a detailed assessment of heat and mass transfer limitations was conducted using both experimental and simulative data, providing essential insights for reliable kinetic measurements.

[1] Gros Tabea, et al. “Fundamental insights into heat and mass transport phenomena in single pellet string reactors based on the exothermic CO2 methanation reaction.” Chemical Engineering Journal (2025) 160863.

https://doi.org/10.1016/j.cej.2025.160863