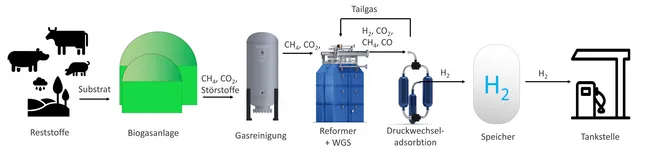

The BMWK-funded project "BioH2Ref" will conclude on December 31, 2024, as a resounding success. In this project, the Bavarian company BtX energy GmbH, in collaboration with the Institute of Industrial Furnaces and Heat Engineering at RWTH Aachen University and the Schleupen family from Lefkeshof in Krefeld, has made a globally unique technology widely recognized: hydrogen directly from the farm—clean and environmentally friendly, like organic milk from a farm shop. In April, the project received the first valid certificate for green hydrogen in the German fuel market, and now, as a final surprise, a gift from Santa Claus marked its conclusion.

Three intense project years have come to an end, with an early Christmas present in the form of a DIN-A4 sheet filled with technical data. During the last project year, the partners worked day and night to meet and exceed their goals. While the plant initially faced typical startup difficulties, parameter studies and different control scenarios during testing—supported by scientific guidance—led to an increase in plant efficiency from 45% to 60% and the achievable nominal output from 70% to over 110%. The purity of the hydrogen, as per DIN 17124 for fuel cell vehicles, had already been confirmed several times. However, one challenge remained until the very end: achieving technical purity of 99.999%, known as 5.0 in technical terms—the benchmark for value in the industrial gas market. This was successfully accomplished in the final month of the three-year project.

Major Milestones Achieved

In addition to the certification obtained in April, qualifying the hydrogen as an advanced biofuel with an astonishing CO2 reduction of over 200% (see press release from April 2), and its approval as the first green hydrogen in Germany's fuel sector (THG quota market), achieving market readiness was the final major milestone.

Conclusion and Market Launch

This ambitious accomplishment was a fitting crowning achievement for the project. Currently, a commercial plant with four times the capacity is under construction. In the coming years, it will produce up to 150 tons of hydrogen from agricultural residues annually, supplying up to 20 trucks for daily operations. In 10 years, "I refuel with biohydrogen" could become as common as "I buy organic milk." The Krefeld plant will continue to receive scientific support under the "BioH2Log" project, launched later and also funded by the BMWK. This project, involving the Chair of Plant and Process Technology at the Technical University of Munich, still holds great potential for further optimization. Discussions for a follow-up project with even more ambitious goals are underway. Starting in 2025, the plant is expected to feed its first quantities of hydrogen into the regular regional gas market, thanks to the newly obtained purity certification.

The project team extends its heartfelt thanks to the BMWK, the project management agency Jülich, and all other participants for their trust and support.

Hydrogen Purity Levels

Purity determines price, but definitions vary. For fuel cell vehicles, DIN EN 17124:2018 addresses the sensitivities of fuel cells, allowing only 0.2 parts per million (ppm) of carbon monoxide, a catalyst poison, while up to 300 ppm of harmless helium or nitrogen are permitted. In trade and technical applications, purity is expressed differently: the fuel cell standard translates to approximately 3.7 purity (99.97%), with three nines and a seven. For higher-value applications, 5.0 purity is typically required—only 10 foreign particles per million in hydrogen.

Biohydrogen in the Legal Context

At the start of the project, many regulations were unclear. However, the project team contributed to shaping the framework to enable biohydrogen from agricultural farms to find its niche. Today, it is recognized EU-wide as an advanced biofuel in the mobility sector and can be credited toward the CO2 reduction targets of individual countries. The German government approved national recognition in 2021, enabling substantial additional revenue through the THG quota market, although this market is currently sluggish for other reasons. In technical applications, the benefits extend to CO2 taxes and emissions trading. However, burning biohydrogen outright is not advisable—it can be done with biogas instead.