Chair of Technical Electrochemistry (TEC), Prof. Dr. Hubert Gasteiger

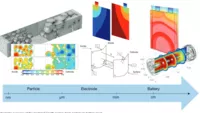

The determination of electrode and electrolyte parameters is essential for the modelling of Li-ion batteries. The parameters determined include geometrical parameters such as tortuosity (labyrinth factor) and porosity as well as material properties in the electrolyte such as ionic conductivity, diffusion coefficient and transfer coefficient.

Chair of Digital Catalysis, Prof. Dr. Helge Stein

In modeling, we apply machine learning techniques to improve our understanding of chemistry. Beyond simply predicting properties, we use these methods to quickly analyze, organize, and visually represent data. Our goal is to use these tools to gain a better insight into the underlying physicochemical processes. Our work spans battery research and catalysis. In battery research, we are particularly interested in formation dynamics and nonlinear charging processes. Our machine learning models work for any chemistry (including Na), any form factor, any test plan, and any diagnostic cycle length.

Chair of Automotive Technology, Prof. Dr.-Ing. Markus Lienkamp

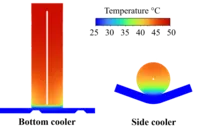

The FTM’s modeling expertise spans from microscopic material-level analysis to macroscopic grid integration and operational optimization of battery electric vehicles. Our single-particle modeling, combined with anode potential regulation, enables precise representation of internal cell processes, allowing for time- and lifetime-optimized fast charging. Thermal modeling coupled with CFD simulation allows us to accurately replicate thermal effects within battery cells to enhance thermal management and fast charging while ensuring operational safety. Operational safety is further addressed through modeling of thermal runaway and thermal propagation. Machine learning approaches and (semi-)empirical methods for aging modeling and lifetime prediction complete the cell modeling capabilities. Additionally, we have package models for integrating various battery architectures into vehicle spaces. Finally, we focus on grid integration modeling as well as operational strategy models for private cars and commercial vehicles to optimize range, efficiency, and charge stop planning within route planning.

Chair of Electrical Energy Storage Technology (EES), Prof. Dr.-Ing. Andreas Jossen

The current focus of this partner with regard to modelling is in the field of lithium-ion technology. This includes spatially resolved, detailed physicochemical models as well as ageing/life span models and models for the description of multicellular systems. In addition to electrochemical properties, mechanical and thermal properties are also taken into account in the models. The modelling tasks at EES also include the simulation and experimental validation of the models.

Physics of Energy Conversion and Storage, Prof. Aliaksandr Bandarenka

The properties of the electrified interface between electrode and electrolyte determine the performance of a battery. The rate at which intercalation occurs, for example, an essential process in lithium-ion and sodium-ion batteries, is not only given by the electrode materials or electrolytes used. The properties of the interface between these two also have a decisive influence. In our research, we mainly investigate these essential properties of the interface in order to develop better battery systems.

Institute for Computational Mechanics, Prof. Dr.-Ing. Wolfgang A. Wall

Solid mechanics plays a significant role in the evaluation of cyclability and service life especially in solid-state batteries. For this reason, the Institute for Computational Mechanics develops simulation models focusing on the interaction between electrochemistry and solid mechanics in geometrically resolved microstructures of solid-state batteries. This includes the solid mechanics and the electrochemistry at the interfaces of the components of a battery cell as well as the transport phenomena within the components. The simulation models are combined with statistical methods in order incorporate existing uncertainties, such as uncertainties in material parameters.