The power-to-methane concept represents a promising chemical storage technology to adapt surplus energy from renewable sources to the current energy demand. This is realized via the catalytic conversion of green H2 and CO2 to methane, which can be fed directly into the existing natural gas grid.

For an efficient CO2 methanation, an active, selective and stable catalyst is a prerequisite. Ni-Al catalysts are ideal candidates in this respect and are used on an industrial scale. The catalyst shape also has a significant influence on the catalytic performance. While conventional catalyst molding techniques are limited in terms of shape complexity, additive manufacturing offers new opportunities in the field of catalyst development.

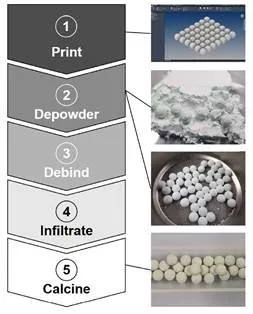

Recently, a new publication from the Chair I of Technical Chemistry demonstrates the successful fabrication of Ni-Al catalysts via the powder-based Binder Jetting process. The catalysts showed high loadings as well as a high dispersion of nickel and initial reactor studies also confirmed the catalytic activity. 3D printing of active catalysts shows future potential in developing novel catalyst geometries especially in terms of optimizing catalytic performance.

DOI: https://doi.org/10.1016/j.apcata.2022.118760

[1] Bui, Hanh My, et al. “3D Printed Co-Precipitated Ni-Al CO2 Methanation Catalysts by Binder Jetting: Fabrication, Characterization and Test in a Single Pellet String Reactor.” Applied Catalysis A: General (2022): 118760.