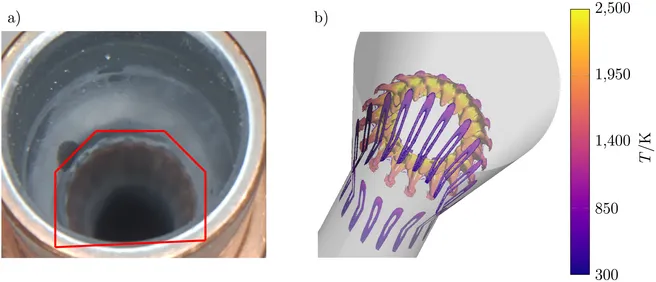

Various industries, such as aerospace, automotive, power generation, and medical sciences, apply high-velocity oxygen-fuel (HVOF) thermal spraying to manufacture temperature and wear-resistant coatings. In the present study, we investigate particle depositions on the convergent nozzle walls of HVOF spray guns. These depositions reduce nozzle lifetime and degrade operation stability and reliability.

We performed fluid-mechanical simulations of the reactive, particle-laden compressible flow through a typical thermal spray gun nozzle to determine the conditions at which particles deposit on the nozzle wall. We identified the radial velocity that the particles have near the central nozzle axis as the critical parameter. This critical velocity decreases with particle diameter and increases with the downstream location at which particles deviate from the nozzle center.

While we have characterized the conditions resulting in particle depositions on the convergent nozzle walls, the mechanism causing these conditions is a target for future research. Our findings suggest that single particle-particle collision events do not create sufficient radial particle momentum to reach the critical particle velocities. Also, we use the gained insights to propose mitigating measures against particle depositions.

Source: www.sciencedirect.com/science/article/pii/S0257897224010119