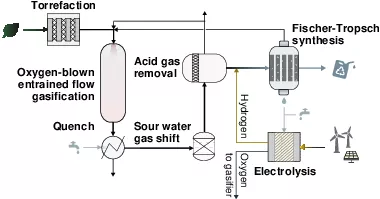

A highly integrated BtL process is modeled in detail using Aspen Plus®. To improve process performance, the integration of green hydrogen and oxygen from water electrolysis is modeled and the use of polymer electrolyte membranes and solid oxide electrolysis at elevated temperature is compared.

Adding hydrogen from electrolysis to the BtL process can more than double the product yield. Improving fuel production comes at the price of higher hydrogen demand. With a biomass input of 200 MWth, this results in electrolyzer sizes between 120-320 MWel, depending on the process configuration and electrolysis technology used. The detailed process models show the high potential for increasing carbon efficiency up to 67%-97% by integrating renewable energy into a biomass-to-liquid process [more].

New publication on the production of renewable fuels at LES

TUM.PtX News |