Electrifying the Production of Green Chemicals and Fuels - Novel Advances in Biomass Conversion

TUM.PtX News |

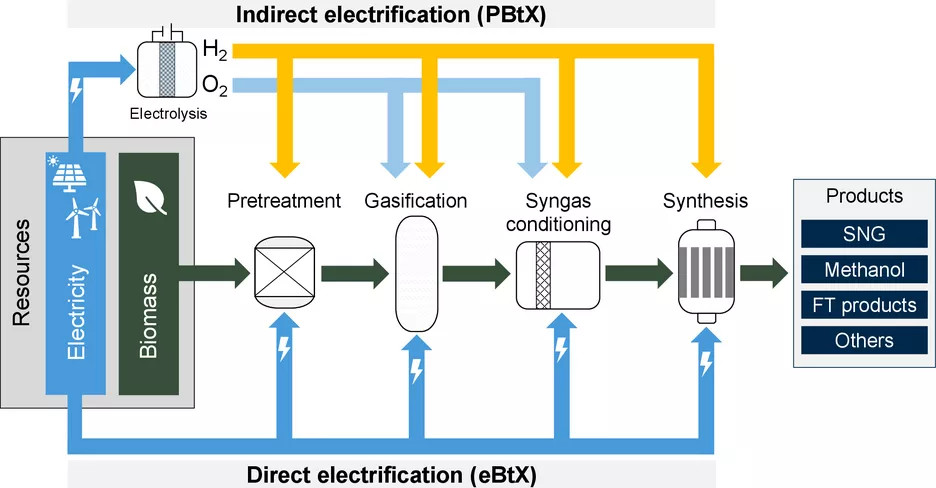

The focus is on gasification-based processes for the conversion of biomass, a proven route known as Biomass-to-X (BtX), with applications in catalytic synthesis for the production of green chemicals and fuels. As biomass is a finite resource, the publication highlights the importance of maximizing product yield for efficient use. Electrification is a promising technological pathway that offers several advantages over conventional BtX and Power-to-X (PtX) processes. Electrification options are divided into direct and indirect processes. While indirect processes add hydrogen from water electrolysis (Power-and-Biomass-to-X, PBtX), direct electrification (eBtX) integrates electricity into certain process steps and offers high efficiency by converting electricity into various forms of energy such as heat, electrochemical energy or plasma.

In the CES analysis, each electrification option is examined in terms of process performance, maturity, feasibility, plant location, space requirements and dynamic operation, providing an insight into the range of technologies available. In particular, H2 addition to PBtX processes is of interest as it offers significantly improved carbon efficiency and product yield. The technology has a high level of technological maturity and the system and process benefits are supported by extensive simulation work in the literature. However, the report points to a research gap in direct electrification (eBtX) by highlighting the low level of technological maturity and calling for comprehensive studies at both plant and system level.

The paper outlines the medium-term path that is indicated by a careful analysis and the role of electrified processes in the use of biomass conversion. The paper is a call to action for science and industry to join forces in the areas of P/eBtX. A cleaner, greener future is moving within reach.

DOI: 10.1039/D3EE02876C (Review Article)

Energy Environ. Sci., 2024, Advance Article

All sectors must be defossilized and decarbonized in order to reduce greenhouse gas emissions and thus mitigate the consequences of climate change. Sustainable biomass and residues are important renewable alternatives for replacing fossil resources, especially for sectors such as transportation or the chemical industry, which are also dependent on fossil resources in the medium and long term. The conversion of lignocellulosic biomass by gasification into synthesis gas and further into fuels or chemicals such as methane, methanol, dimethyl ether or Fischer-Tropsch syncrude is a promising technology option (Biomass-to-X, BtX). To fully exploit the potential of biomass resources while reducing greenhouse gas emissions, this publication discusses the direct or indirect electrification of BtX processes with renewable electricity. For example, electricity can be used to power individual process steps (direct electrification) or to generate green hydrogen educt in chemical reactions (indirect electrification). These processes can have significantly higher economic, energetic and ecological performance than conventional biomass-based (BtX) or electricity-based (Power-to-X) processes. Electrified BtX processes therefore have great potential to contribute to the defossilization and decarbonization of the chemical industry and the transport sector.

Contact: Marcel Dossow, Sebastian Fendt

We gratefully acknowledge funding of the projects “Verena” (03EE5044B) sponsored by the German Federal Ministry of Economic Affairs and Climate Action, and “REDEFINE H2E” (01DD21005) sponsored by the German Federal Ministry of Education and Research. In addition, the authors acknowledge the cooperation within the Network TUM.Hydrogen and PtX.